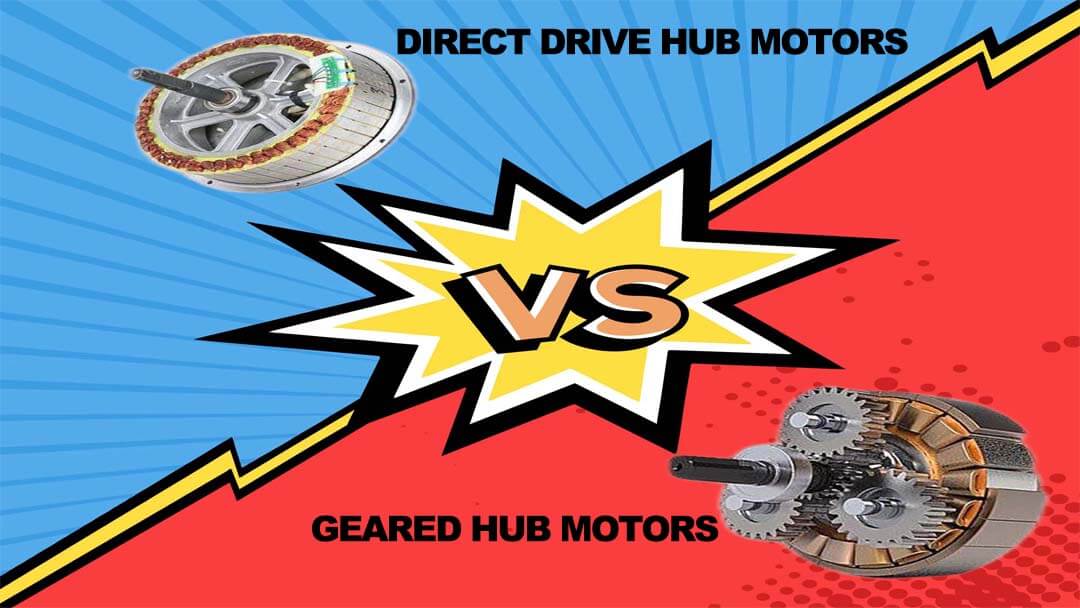

What’s the Difference Between E-bike Geared Hub Motors and Direct Drive Hub Motors?

How much do you know about the inner workings of electric bike motors? Which motor should I use when building an electric bike? Which is better: a hub motor with or without gear? You may have several questions. So far, we've discussed two of the most common types of motors on the market today. Our current inventory includes three Shengmilo e-bikes (mountain e-bike, folding e-bike, commuter city e-bike), all with geared hub motors. Would you like to know what these two different types of motor designs are and which one is best for you? Let us help you find out together!

What is the difference between geared hubs and direct drives?

Geared and gearless, respectively, refer to how the power from the motor is transferred to the wheels. So what exactly is the difference between them? So, we'll detail their pros and cons, starting with their weight, speed, range, and more.

Overview of Geared Hub Motors

The key concept to remember is that the gears in the hub reduce the rapid spin of the motor to a more manageable wheel speed. Gearing is necessary because the motor spins much faster than the wheels of an e-bike. Geared in-wheel motors are the most common and cost-effective type of in-wheel motor.

A gear reduction system connects the geared hub motor to the stator. When the casing rotates, the inner gear rotates at a faster rate. The slower the wheels spin, the faster and more efficiently the motor runs.

Gearless (Direct Drive) In-Wheel Motor Overview

These e-bike components are also known as "direct drive" or "brushless" motors. In this case, the motor shaft and the shaft passing through the center of the motor can be interchanged. The copper coil is fixed to the shaft. When all these parts are combined, they form what is called a stator. When current flows through the stator and magnets outside the motor, a magnetic field is created. The motor of the bicycle is powered by the way the magnet moves after being pulled.

Advantages of geared hub motors

Geared hub motors produce more torque and create less drag, making them ideal for low-speed, high-torque applications such as those on Class 1 and Class 2 e-bikes that typically require motor assistance up to 20 mph. Due to their high torque output, they may be better suited for steeper slopes (usually, you have to get big and heavy without gears to produce similar torque).

Compared to gearless alternatives, they become smaller and lighter. Gears in the hub increase the efficiency of the motor, making a geared hub motor smaller and lighter than a gearless motor. Geared hub motors typically weigh 2 to 4 kg (4.4 to 8.8 lbs) and have a smaller diameter, so they are not noticeable on the bike.

Most geared hub motors have flywheels that make it easy to pedal even without electric assist, keeping the price down. In general, gear systems are less expensive to manufacture and acquire.

Disadvantages of geared hub motors

Some geared hub motors are loud, but manufacturers have found ways to make them quieter by using helical gears and other innovative methods. The only reliable way to determine if the noise level of a particular geared hub motor is acceptable is to test it.

The geared hub motor appears to be worn out and may need to be replaced (though usually, this takes at least a few thousand miles; better quality motor gears will last thousands of miles). However, since the gearing is small and designed to spin the wheel quickly, heavier riders and riders with a lot of cargo may have issues with long-term durability. This is especially true if the engine is constantly working hard on steep hills.

Advantages of direct drive (gearless) in-wheel motors

Fast: For the fastest electric bikes, such as 28 mph Category 3 bikes, To transfer power from the pedals and motor to the road surface, two variables must be considered: speed and "torque," or steering effort. Gearless motors are more efficient at higher speeds due to their lack of torque.

Service life: the ability of the motor to charge the battery while acting as an electronic brake (regenerative braking). As amazing as it sounds, the physics suggests that the amount of energy returning to the battery may disappoint you. Regenerative braking helps bigger, heavier cars more because the amount of energy they lose is proportional to their size.

On the other hand, regenerative braking is great for long descents because it means you don't have to brake all the time. This keeps the brakes from getting too hot and the pads from wearing out.

Direct-drive hub motors are quiet because there is only one moving part (the wheel spinning on its axis), and the magnets and copper wraparound hub don't touch each other. Some of the quietest motors have gears that are so tightly interlocked that the motor runs without any gear contact.

Disadvantages of direct drive (gearless) hub motors

To compensate for the lack of torque in the gearless design, they had to be bigger and heavier. Therefore, gearless motors require more effort to propel them and climb steep inclines. weighs 4–9 kg and measures over 20 cm (8 inches) in diameter.

Slow down your pedaling speed: While a well-designed gearless hub motor can achieve impressive low-speed efficiency, it can never match the low-speed efficiency of a geared hub motor that can run at higher speeds. Since there is no flywheel, it is more difficult to pedal without the help of an electric motor. They lack the "torque" that "torque" has and cannot climb mountains.

Because starting the direct-drive motor requires new energy from the battery, its lifespan will be shortened if used frequently in stop-and-go traffic. Additionally, when not fully accelerated, the magnetic fields produced by these motors create resistance when pedaling or coasting, making them sluggish and difficult to pedal.

Direct-drive motors cannot use the same fully charged batteries as gear motors because they are heavier and require more energy to accelerate in the first place. In most cases, the reduction in range is trivial.

Geared Hub Comparison Direct-drive hub motors: which is best for you?

For those who value portability over durability, a gear motor is a great option, as it allows for greater stealth, free rotation, and range while remaining relatively lightweight.

If you want to trust the motor more, drive at higher speeds (20 mph or more), and have a motor that lasts a long time and is quiet, then the super-powerful direct drive is a good choice.

However, keep in mind that geared and gearless motors have many similarities. There are cadence sensing, torque sensing, and throttle control options. Finally, if you buy a high-quality electric bike with a high-quality hub motor, you will have a great time.

What is the best electric bike motor for you?

Once you have a basic understanding of the various motor types and their characteristics, we'll tackle your most pressing question: how to choose an e-bike motor. Please carefully consider your requirements before making a decision. Whether you plan to use your e-bike to commute to and from work or ride small hills, a geared hub motor will come in handy. Why? Not only is it light and lightweight, but it has a long range and requires little maintenance. If you plan to use it for tough mountain trails or intense riding, we believe the gearless hub motor will appeal to you and provide you with more fun. It's entirely up to you to decide.

Do you all have a better understanding of the difference between geared and gearless hub motors? Which do you prefer? Which is better: the former is portable, light, and efficient, while the latter is fast and silent? You can help spread the word about electric bikes by forwarding Shengmilo's blog to your friends.

Leave a comment