Shengmilo Electric Bike Motor Maintenance Tips | Complete Guide to Extending Motor Lifespan

Electric bikes have become a popular choice for daily commuting and recreational riding, with the motor serving as their core power component. Proper maintenance not only ensures stable motor performance but also significantly extends its lifespan, helping you keep the motor running efficiently and avoid malfunctions caused by inadequate care.

1. Understanding Motor Structure and Common Issues

Before performing maintenance, it is crucial to understand the motor’s structure and common problems. Shengmilo electric bikes are generally equipped with brushless DC motors (BLDC Motor), which are known for high efficiency, low noise, and relatively simple maintenance, but they still contain components prone to wear:

-

Bearings: Bear rotational loads and may wear over time due to friction.

-

Gears and drivetrain: Core components for power transmission, requiring proper lubrication.

-

Coils and magnets: Key internal components of the motor, which should be protected from water ingress or impact.

-

Controller connection ports: Loose or corroded wires can lead to motor malfunctions.

Common issues include increased noise, reduced power, intermittent startup, or complete failure to operate. Proper maintenance can greatly reduce the likelihood of these problems.

2. Daily Cleaning and Protection

✅ External Cleaning

-

Wipe the motor casing with a soft cloth or sponge, avoiding high-pressure water directly on the motor to prevent water ingress.

-

For accumulated dirt or dust, use a clean soft-bristled brush or a hairdryer on the cool air setting.

-

After riding in the rain, promptly dry around the motor to prevent rust or corrosion.

✅ Water and Dust Protection

-

Motors typically have an IP55~IP65 rating but are not fully waterproof.

-

Before riding, check motor connectors and wires for looseness and ensure the waterproof seals are intact.

-

For long-term storage, use a dust cover over the motor to prevent dust and moisture intrusion.

Tip: Avoid high-speed riding in muddy or waterlogged environments to reduce the risk of water or dust entering the motor and causing short circuits or wear.

3. Mechanical Inspection and Lubrication

✅ Axle and Bearing Check

-

Regularly inspect the motor bearings for unusual noise or looseness; rotation should be smooth without resistance.

-

For serviceable bearings, apply specialized grease every 3–6 months to ensure smooth rotation.

✅ Gear and Chain Maintenance

-

The gears and chains at the motor output are high-wear components and should be kept clean and lubricated with chain oil.

-

Check chain tension every 200–300 km of riding and adjust or replace if necessary.

-

Avoid chains that are too loose or too tight, as they reduce power transmission efficiency.

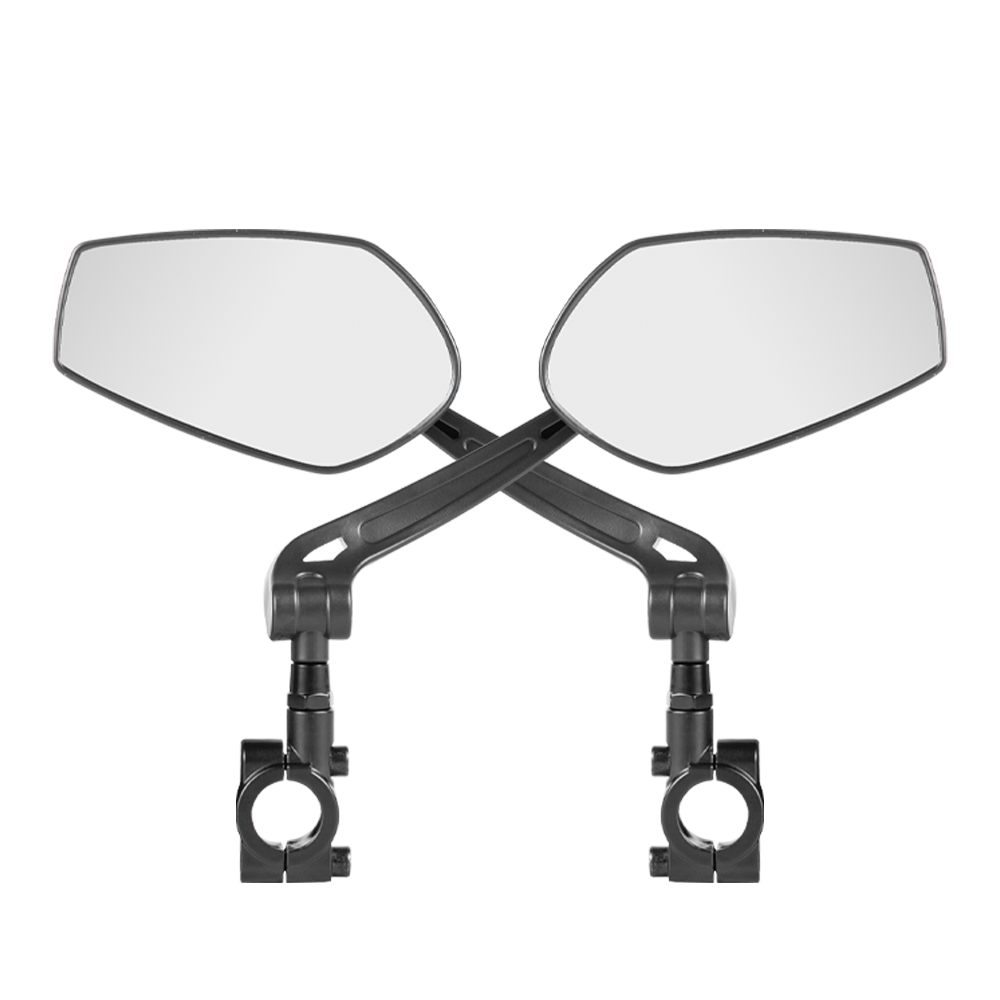

✅ Brake System Check

-

High motor power increases brake load; regularly check brake pad wear.

-

Ensure brake cables and discs are free of debris to maintain riding safety and proper motor load.

4. Motor and Battery Management

Motor performance and lifespan largely depend on battery management:

✅ Battery Charging and Discharging

-

Avoid excessive battery discharge (below 20%), which can overstrain the motor due to low voltage.

-

Use the original charger and follow the principle of “slow charge first, then full charge.”

-

For long periods of inactivity, charge the battery every 1–2 weeks to maintain battery health.

✅ Avoid Overload Riding

-

Prolonged operation at low speed uphill or under full load generates high heat and shortens motor life.

-

Use pedal-assist mode where possible and adjust gears appropriately according to terrain to reduce motor load.

✅ Temperature Management

-

High temperatures accelerate coil aging. If the motor becomes too hot after riding, allow it to cool before continuing.

-

Avoid prolonged parking under direct sunlight to prevent excessive motor temperature.

5. Regular Professional Maintenance

-

Every 6–12 months, take the motor to a professional service center for internal inspection, including coil insulation, brush wear, and gear teeth condition.

-

For brushless DC motors, also check the Hall sensors and controller connections for proper operation.

-

Professional inspections help prevent potential faults and extend motor lifespan.

6. Optimizing Riding Habits

Good riding habits significantly reduce motor wear:

-

Smooth acceleration and deceleration: Avoid sudden sprints to reduce gear and bearing load.

-

Avoid continuous high-speed load: Prolonged full-load or high-speed riding can overheat coils.

-

Use pedal-assist lightly: Combine pedaling with assist mode to reduce motor power output pressure.

-

Avoid complex terrain: Steep slopes and muddy roads increase motor load; choose suitable routes.

8. Long-Term Maintenance Recommendations

-

Regularly check the motor mount and bolts to prevent loosening.

-

Keep the motor surface clean.

-

Use the pedal-assist modes appropriately.

-

Follow the manufacturer’s manual and use original parts and lubricants.

-

Pay attention to environmental conditions and avoid prolonged riding in rain or snow.

By following these practices, the Shengmilo motor’s lifespan can be extended by 2–3 years or more, while maintaining efficient power output.

Summary

The motor is the core power component of a Shengmilo electric bike. With proper maintenance and reasonable use, it can operate efficiently for a long time. Daily cleaning, protection, lubrication, proper battery management, and optimized riding habits are key. Combined with regular professional inspections and troubleshooting, you can effectively extend the motor’s lifespan and enjoy a smooth and safe riding experience.

Leave a comment